JBES welcome all respective authors to submit their research paper / manuscripts, thesis paper in the field of Environmental Sciences, Biology, Biodiversity, Species diversity, Ecology, Taxonomy and many more via online submission panel

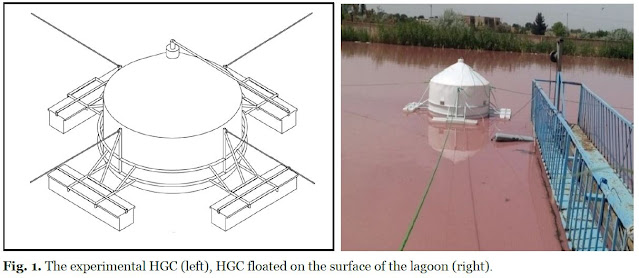

Peghah Dairy Plant in Tabriz, Iran, near Shahid Madani International Airport uses a combination of two wastewater treatment systems, namely, lagoon and activated sludge system. Presence of a lagoons near airports can affect passengers getting off the planes due to unpleasant odor and has always been a controversial issue from the urban planners’ point of view. Most of the biological activities in the lagoons are anaerobic producing odorous gases as a result. On the other hand, biogas produced by biological activities enters into the atmosphere, contributing to global warming. To avoid an environmentally adverse effects of the emitted gases from the lagoon in Peghah Diary Plant in Tabriz, the possibility of using the collected gases from the lagoon in heating processes within the plant was studied. In this study, a single experimental unit of an innovative gas collector, named Honeycomb Gas Collector (HGC), was designed and constructed to cover the surface of the lagoon and lagoon inputs were recorded and samples of biogas from the lagoon were collected and analyzed during April 2016 until March 2019. The highest daily amount of 44.82 m3 biogas from the entire lagoon was recoded in August 2016. Temperature and pH had the most and least significant effect on biogas production respectively. There was a strong relationship with a coefficient of 0.94 between the temperature and the volume of biogas produced. This system proved to be less costly and maintenance free method for covering the lagoon surface.

Introduction

Peghah Dairy Plant is located in north of Tabriz, Iran, about 1.7km far from Shahid Madani International Airport. Passengers getting off the planes as well as nearby residents are affected by unpleasant odor emitted from lagoon. About 330 to 400 tons of raw milk is delivered to the diary plant for processing on daily basis. Around 1000m3/day of effluent is discharged from the plant. The capacity of anaerobic sewage and the activated sludge systems are 7500m3 and 800m3, respectively.

The high volume of wastewater produced by diary industries, along with their significant contamination, have led to enforcing strict regulations for these industries in different countries. Organic matter in dairy effluents comprises mainly of carbohydrates, proteins, and fats (Vlyssides et al., 2012). The dairy industries are one of the most polluting industries not only because of their high volume of wastewater, but also due to its characteristics (Kushwaha et al., 2011). Wastewater from such industries often cannot be treated by aerobic methods alone because of its high toxicity and chemicals as well as high Biological Oxygen Demand (BOD). The amounts of suspended solids are 2000gr/m3, COD (Chemical Oxygen Demand) 3700gr/m3, and BOD 2500gr/m3 (Sabliy et al., 2009). The combined method is the best for the treatment of dairy wastewater. Researchers have proposed an anaerobic-anaerobic treatment method for dairy wastewater treatment (Kushwaha et al., 2011).

The average consumption of milk per capita per year in Iran is about 91kg, while the average consumption in the world is 156kg and in European countries it is 300kg. In order to increase per capita consumption of milk in the country, the volume of milk and dairy products will have to be increased and this will result in producing more wastewater. The wastewater of the dairy industries is warm and has high COD, this makes it suitable for anaerobic treatment in the first stage. Anaerobic processes produce significant amounts of methane. Also the unpleasant odor production occurs in this stage. Whey is one of the most polluting wastewater. Its biochemical constituents are rich in organic matter (Shete, and Shinkar, 2013; Rajshoori et al., 2000). Worldwide cheese production generates more than 145 million tons of whey each year. Wastewater from the cheese industry has a very high level of COD about 50,000 to 80,000mg/L. (Najafpour et al., 2008).

READ MORE

Research Paper on vegetables | Towards valorizing spinach and amaranth’s leaves in Eastern democratic republic of Congo | IJAAR 2019

Common anaerobic methods in dairy wastewater treatment mainly include Up flow Anaerobic Baffled Reactor (UABR), Up flow Anaerobic Sludge Blanket reactor (UASB), up flow Anaerobic Fixed Biofilm Reactor (UAFBR), Anaerobic Lagoon and common aerobic methods include conventional Activated Sludge, Moving Bed Biofilm Reactor (MBBR), Sequencing Bach Reactor (SBR) based on activated sludge method. Sometimes the post-treatment phase for the dairy industry wastewater is carried out by physio-chemical methods which include coagulation and flocculation methods. These methods can be referred to as membrane processes such as Nano filtration and reverse osmosis (Kushwaha et al., 2011).

Lagoon systems are suitable for wastewater treatment in food processing industries. Anaerobic lagoons in the US and Australia have high acceptability due to their ability to treat high BOD wastewater, availability of large areas for lagoon construction, and low operating costs (Johns, 1995). It should be noted that due to space constraints in Europe, demand for lagoons is low and they are more inclined to use reactor systems. In Asia, lagoons are mostly used for palm oil purification (BOD>25000mg/L) (Laginestra, 2012).The main advantage of using lagoon systems is the ease of construction, operation, and maintenance. However, a larger land is needed to build it. It is possible to use the lagoon if the whole complex of treatment system is located out-of-town space of city. Warm weather improves bacterial growth conditions. The pH of the lagoon should be 7 to 8. At pH below 6.5, the condition becomes acidic, odor production and sludge production increases. Under normal anaerobic conditions, organic matter is converted to biogas during the process of Hydrolysis, Acidogenesis, Acetogenesis and Methanogenesis. If there is no equilibrium between Acidogenesis and Methanogenesis phases, the odor is more likely to be produced (Zhang et al., 2013).

In UASB, Fat, Oil and Grease (FOG) may accumulate. The growth of dispersed grains and the accumulation of sludge and FOG leaching from the reactor cause severe operational problems. To overcome these problems, pre-treatment methods such as fat removal by Dissolved Air Flotation (DAF) or the use of some contact reactors will be required (Rilo et al., 2014). This operation needs a long launch time. The reactor requires a skilled operator and continuous monitoring operations. (Rajeshwari et al., 2000).

In the UABR, the wastewater is treated by passing through a number of upward and downward chambers. In this type of reactor, the solids retention time in the reactor is longer than the hydraulic retention time. The severe effect of shocks gradually diminishes on Sequential baffles. Due to the accumulation of gas in the UABR reactor, there is no access to the reactors in case of any problems or to check overflows.

To increase the efficiency in UABR, the media is mounted in the upstream section of the reactor (UAFBR), which is used to prevent sludge escape as well as increase biological contact and subsequently increase the treatment efficiency.

Each of the anaerobic methods already mentioned above require their own equipment and has its own complications. The biogas produced by the anaerobic process includes CH4 (70-60%), CO2 (40- 30%), H2S (10-2000 ppm), N2 (less than 2%), NH3, H2, CO, and O2 (Siefers, 2010). The biogas odor arises mainly from H2S, Volatile Organic Compounds (VOCs), and NH3. H2S is extremely odorous and corrosive and even in very small quantities causes severe corrosion in pipes and other equipment (Krich, 2005).

The overall goal is to prevent the releasing of biogas and some odorous gases produced during the anaerobic process into the atmosphere. In the present work, a single experimental unit of an innovative gas collector, named Honeycomb Gas Collector (HGC), was designed and constructed to cover the surface of the lagoon for reducing odor, especially in windy days and preventing methane release into the atmosphere. Then, the amount of methane and hydrogen sulfide in biogas and the factors affecting biogas production were studied over three years.

Get the full articles by following this link J. Bio. Env. Sci. 15(3), 1-9, September 2019.

Reference of the articles :

Johns MR. 1995. Development in wastewater treatment in the meat processing industry: A review, Bioresource technology, volume 54(1995) – 203-216. BioSource Technology 54 (1995) 203-216

Krich K, Augenstein D, Batmale JP, Benemann J, Rutledge B, Salour D. 2005. Biomethane from dairy waste. A Sourcebook for the Production and Use of Renewable Natural Gas in California. prepared for Western United Dairymen Michael Marsh.

Kushwaha JP, Srivastava VCH, Mall ID. 2011. an overview various technologies for the treatment of diary wastewaters, Critical reviews in food science and nutrition 51, 442-452.

Laginestra M. 2012. Covered Anaerobic Lagoons Final Report. published by Meat & Livestock Australia Limited ABN 39 081 678 364 (MLA).

Najafpour GD, Hashemiyeh BA, Asadi M, Ghasemi MB. 2008. Biological Treatment of Dairy Wastewater in an Upflow Anaerobic Sludge-Fixed Film Bioreactor, American-Eurasian J. Agric. & Environ. Sci., 1818-6769 4(2), 251-257.

Rajeshwari KV, Balakrishna M, Kansal A, Lata K, Kishore VVN. 2000. State of the Art of Anaerobic Digestion Technology for Industrial Wasetwater Treatment, Rnnewable and Sustainable Energy Reviews 4(2000), 135- 156.

Rilo SM, Coimbra RN, Villacorta JM, Otero M. 2014. Treatment of Dairy Industry Wastewater by Oxygen Injection, Journal of Cleaner Production.

DOI: 10.1016/j.jclepro.2014.08.026.

Sabliy L, Kuzminskiy Y, Gvozdyak P, Lagod G. 2009. Anaerobic and Aerobic Treatment of Wastewater of Milk Plants, Proceedings of ECOpole- Vol. 3, No. 2, 373-378.

Shete BS, Shinkar NP. 2013. Dairy Industry Wastewater Sources, Characteristics & its Effects on Environment. Research Article. International Journal of Current Engineering and Technology. 2277 – 4106. vol.3, No.5. 1611-1615.

Siefers AM. 2010. A Novel and Cost-Effective Hydrogen Sulfide Removal Technology Using Tire Derived Rubber Particles, Theses and Dissertations, Iowa State University, 11281.93 pages.

Stenglein RM, Clanton CJ, Schmidt DR, Jacobson LD, Janni KA. 2011. Covers for Mitigation Odor and Gas Emissions in Animal Agriculture: www.exrension.org/pages/15538/air-quality-in-animal-agriculture.

Vlyssides A, Tsimas E, Barampouti EM, Mai S. 2012. Anaerobic Digestion of Cheese Dairy Wastewater Following Chemical Oxidation. Bio systems engineering. 15375110. II 3, 253-258

Zhang XL, Yana S, Tyagi RD, Surampalli RY. 2013. Odor Control in Lagoons. Journal of Environmental Management. 124, 62-71.

DOI: 10.1016/j.jenvman. 2013.03.022

0 comments:

Post a Comment